Mining

ACCESS

SOLutions

Mining Access Systems for Safe and Efficient Operations on Site

Safetylyne Mining Access Systems: Built for Durability, Safety, and Efficiency

When it comes to access systems in the mining industry, Safetylyne leads the way in delivering innovative, durable, and highly effective solutions.

From walkways and plant platforms to modular platforms and truck wash platforms, mobile and fixed stairs, our systems are engineered to withstand the toughest conditions, ensuring safe and efficient access for your teams. With decades of experience and a focus on compliance with Australian height safety standards, we provide the mining industry with trusted access solutions that enhance safety and operational efficiency.

Access Solutions for Mining Sites

Mining operations require unique, flexible, and reliable access systems to manage complex work environments. Safetylyne delivers systems designed to meet these challenges, with a range of customisable products:

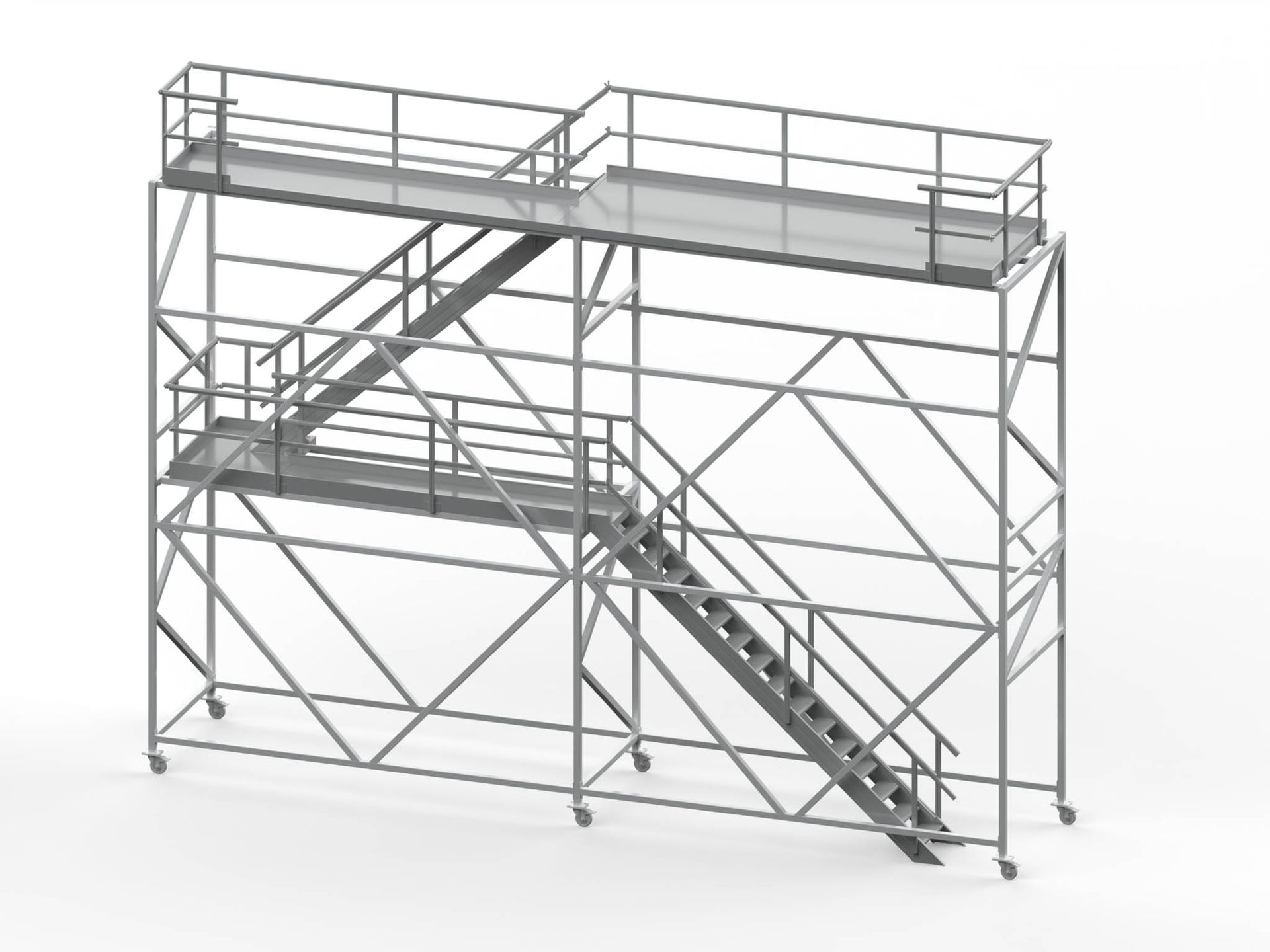

+ Modular Access Systems

Our modular access systems are a game-changer for mining sites.

Designed for flexibility, they can be easily assembled, dismantled, or expanded as your operational needs evolve.

These systems are ideal for areas where temporary access is required or for sites where frequent reconfiguration is necessary.

- Key Features: Quick assembly, durable materials, adaptable configurations

- Applications: Maintenance work, inspection platforms, temporary access points

+ Truck Wash and Maintenance Platforms

Maintaining your heavy machinery fleet is essential for the smooth running of your operations. Our truck wash platforms provide safe, stable access for washing and inspecting heavy mining vehicles. Built to handle suit any size of mining trucks, these platforms ensure workers have the access they need while minimising risk.

- Key Features: Robust structure, non-slip design, resistance to chemical exposure and heat, maximum strength and durability. Choose from mobile or fixed platforms depending on the environment.

- Applications: Maintenance bays, vehicle wash stations

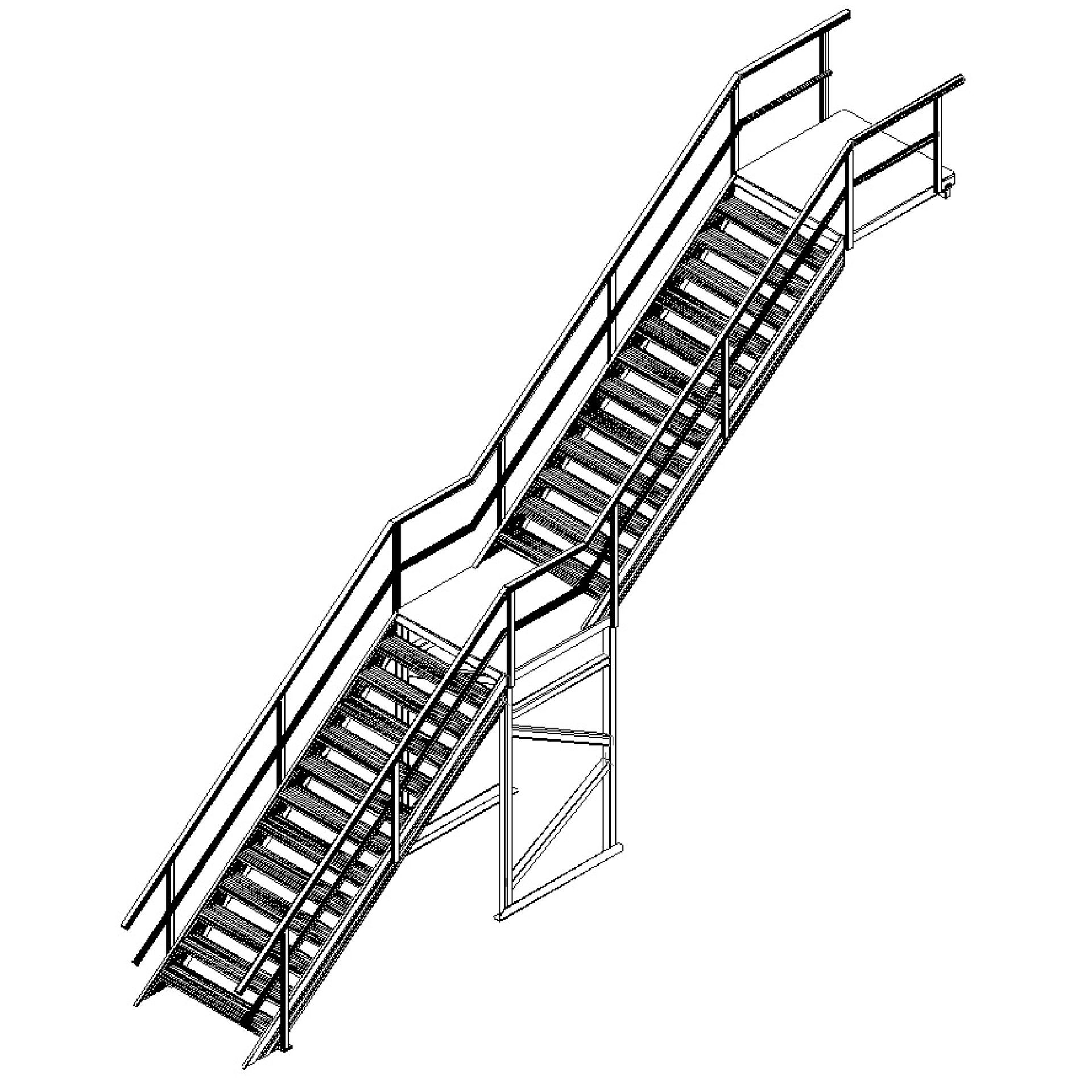

+ Heavy Duty Walkways and Access Platforms

Our mining walkways and plant decks are designed for durability and safety. Built using high-quality aluminium and fiberglass reinforced plastic (FRP), our platforms are engineered to handle heavy traffic and resist corrosion, even in harsh conditions.

Anti-slip surfaces, safety guardrails, and custom configurations ensure your team can work confidently at height.

- Key Features: Anti-slip surfaces, handrails, modular design for easy reconfiguration

- Applications: Conveyor belts, processing plants, high-traffic areas, easy machinery access for compliant work at height.

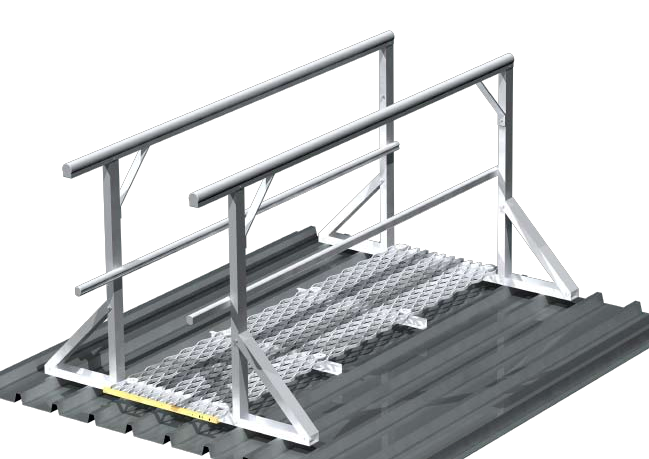

+ Crossover Stairs, Bridges and Platforms

Mining sites often present obstacles such as pipelines, conveyors, and machinery that must be navigated safely.

Our crossover stairs and bridges provide reliable solutions for crossing over hazards without disrupting workflow. They are designed to meet both Australian safety standards and the unique demands of mining environments.

- Key Features: Customisable dimensions, lightweight but durable design, easy installation

- Applications: Safe access over obstacles like conveyors, piping, or uneven terrain

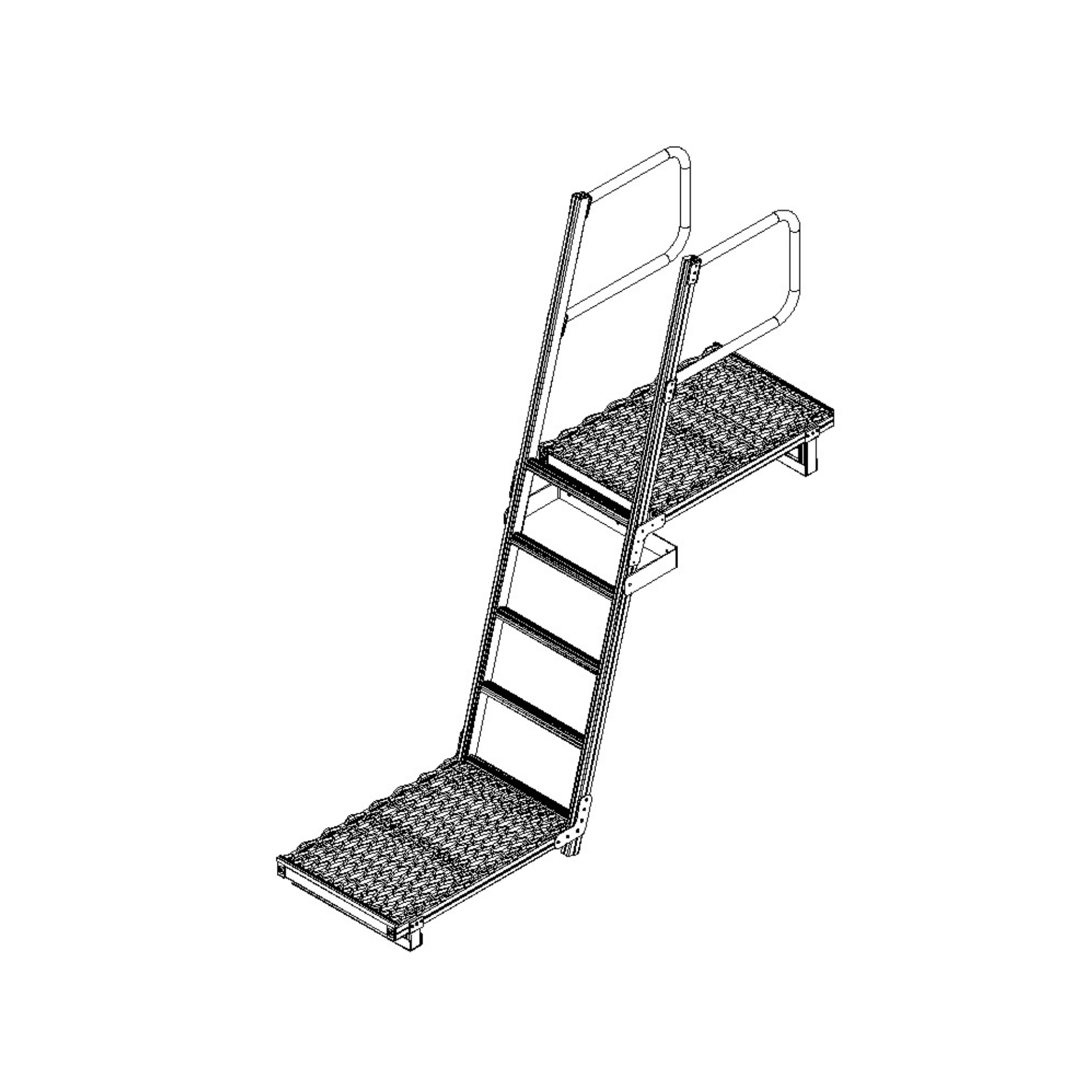

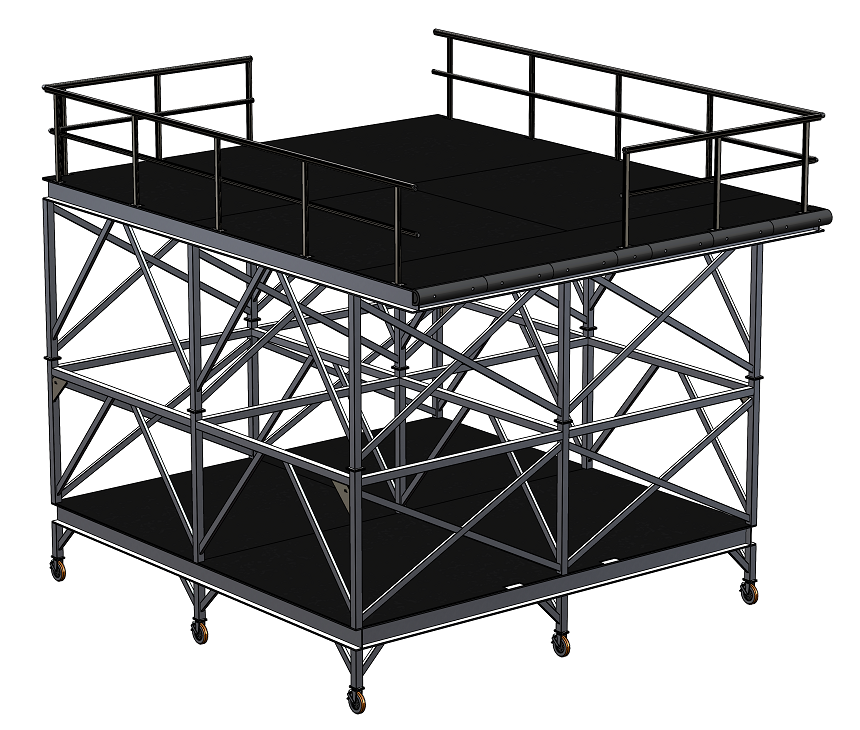

+ Multipurpose Mobile Platforms

For operations that require flexible solutions, our mobile platforms offer unparalleled versatility. These stair platforms can be moved easily across the site, providing safe access to hard-to-reach areas.

Whether for maintenance, repairs, inspections, or any other work at heights , these platforms ensure that your teams are working in a safe, secure and compliant environment.

- Key Features: Portable design, adjustable height, stable footing, non-slip surface, height adjustable options available

- Applications: Equipment maintenance, temporary work areas, emergency access, heavy duty work tasks, truck access, mining haul track access

Custom mobile platforms are fully engineered and constructed from marine-grade aluminium, offering heavy-duty durability for mining workshops.

These platforms can be custom-made to suit all machine makes and models, including compatibility with CAT, Komatsu, Liebherr, and Hitachi trucks.

Features include adjustable height, mesh platforms for grease and oil drainage, large solid wheels for gravel or dirt use, and optional removable or collapsible handrails.

Designed with flexibility in mind, they allow access into truck chassis, over hydraulic boxes, and fuel tanks, with fitter platform stairs at both ends for easy access. Suitable for underground loader access, bridge decks for dozers, and U-shaped configurations to fit over wheels without clashes, they are crane-liftable, forkliftable, and perfect for multiple users.

Reliable Height Safety Solutions for Mining Operations

Effective height safety is crucial for maintaining productivity and protecting workers in mining environments.

With solutions designed for complex conditions, the right safety systems can enhance site efficiency,

reduce risks, and

ensure long-lasting compliance. Our engineered solutions can benefit your operations.

Reliable systems ensure workers have the stability and confidence to perform tasks safely at any height, with components built to endure even the toughest conditions.

+ Custom Platforms and Walkways

Safe access is essential across mining sites, especially in elevated or hard-to-reach areas. Custom-designed mobile and fixed working platforms and walkways provide robust, stable, and compliant solutions, whether stationary or mobile. These systems enable seamless movement across work areas, reducing the risk of falls while supporting productivity and efficiency.

+ Comprehensive Training and Safety Programs

Safety at height starts with well-informed teams. Training programs that teach employees how to identify and mitigate fall hazards can make a significant difference. Programs that emphasise best practices and compliance help build a workforce that’s ready to handle the challenges of working at height in mining operations.

That's why Safetylyne provides consulting on height safety systems, user manuals documentation, as well as site surveys and appraisals to identify potential height safety risks and safety systems solutions.

+ Smart Design for Safer Work Areas

Creating safer workspaces begins with smart, strategic design.

Integrating safety solutions from the ground up helps minimise hazards and improve workflow. By focusing on efficient design from the outset, it’s possible to build environments that support safety and productivity without disruptions.

+ PrioritiSing Safety with the Hierarchy of Control

Effective safety management involves using the hierarchy of control to address risks. Engineering solutions that reduce hazards at the source should take priority, minimising reliance on administrative measures or PPE. Prioritising higher-order controls helps create a safer and more compliant work environment.

+ Purpose-Built Equipment for Height Safety

Not all equipment is suited for the demanding conditions of a mining site. Strong, stable, and purpose-built systems ensure reliable performance, providing safety, durability, and ease of use. Opt for equipment that is designed specifically for complex projects, ensuring teams can work confidently and efficiently at height.

+ OptimiSed Ladder Safety Practices

When ladders are used, following best practices - like avoiding overloading, limiting reach, and preventing misuse - can significantly improve safety outcomes. Consider installing access plant decks and platforms to optimise safety measures at the mine site.

Making the Right Choice for Mining Height Safety Choosing reliable, well-designed access systems means investing in safety, compliance, and long-term operational efficiency.

Effective solutions not only protect workers, but also streamline processes, reduce downtime, and ensure compliance with the most stringent safety standards.

Prioritising quality, engineered safety systems leads to safer, more productive mining environments.

Custom Fixed and Mobile Mine Guardrail Systems for Fall Protection

Fixed and mobile safety rail systems are essential for protecting workers at heights on mine sites. Designed for fall protection, these systems are used around mezzanines, along edges of mobile plant equipment, and other elevated areas.

Customisable to suit specific site needs, fixed and mobile rails enhance safety while ensuring compliance with mining regulations.

Built for durability and functionality, these systems are engineered to reduce risks, improve access, and withstand harsh mining environments. With expert design and advanced manufacturing capabilities, tailored solutions can be created to address unique challenges, providing maximum safety and efficiency for mining operations.

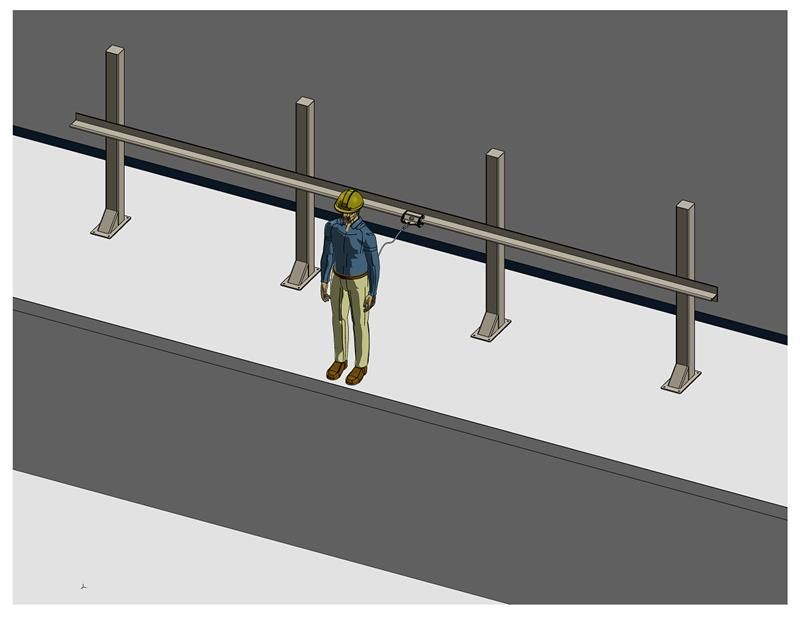

Horizontal Lifeline Rail Systems for Fall Protection

Horizontal lifeline rail systems provide reliable fall protection for workers operating at heights in mining environments. These systems are ideal for areas requiring continuous mobility, such as along conveyor belts, mezzanine or roof edges, or elevated walkways.

Custom-engineered to suit specific site requirements, they ensure workers remain securely tethered while maintaining freedom of movement.

Durable and compliant with industry safety standards, horizontal lifeline rails offer a practical and efficient solution for reducing risks in challenging mining conditions. Designed for ease of use and long-term performance, they are an essential component of a comprehensive height safety strategy.

Learn more about Fall prevention and The Hierarchy of Control in Height Safety.

At Safetylyne, we believe in empowering our clients with the resources they need for safe and efficient operations. We offer comprehensive guides on the installation, maintenance, and usage of all access systems, along with expert consultation to help you choose the best products for your project.

Why Safetylyne is a smart choice for your access needs

We understand that each mining site is different, and a one-size-fits-all solution won’t work. That’s why we provide customisable, modular access systems tailored to your site’s specific needs. Here’s what sets us apart:

- Custom Designs. We work closely with OHS managers and project managers, builders and architects to create tailored access systems that meet the unique demands of each site.

- Compliance. All of our systems are designed and installed in line with Australian safety standards, ensuring your site remains compliant with safety regulations.

- Durable Materials. Our use of high-strength aluminium, steel, and fiberglass reinforced plastic (FRP) ensures long-lasting performance even in the most challenging environments.

- Expert Support.

Our team of experts is always on hand to provide support, from initial consultation to final installation and ongoing maintenance.

Contact Us

For top-quality, custom-engineered and food grade access solutions for your facility, contact Safetylyne today. Our experts are ready to provide comprehensive safety audits, recommendations, and installations to ensure the highest level of safety and efficiency for your operations.

Contact Us

Our Process

Engineered Systems

Our Engineered Systems are a range of meticulously designed and manufactured products that can be integrated into a comprehensive height safety package, custom access solution or supplied individually based on client needs. These products, are manufactured in-house to the highest standards and are not only versatile, reliable and meet industry standards but also exceed client expectations.

They are Access Solved.