Fall Restraint Overhead Rail Systems

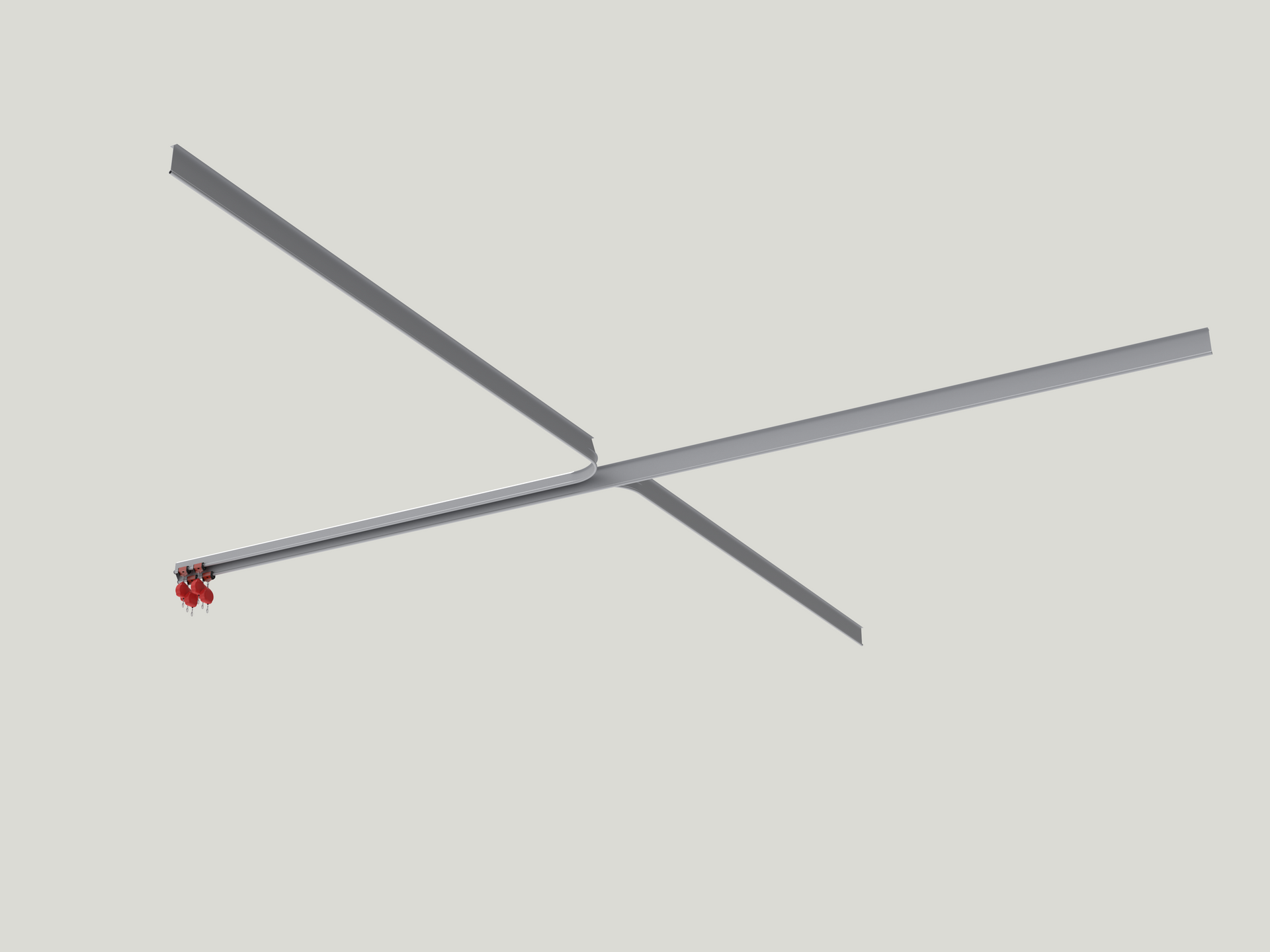

Safetylyne's Fall Restraint Overhead Rail System has been designed and engineered to facilitate continuous attachment for multiple harness connections.

Its robust construction delivers durable and efficient fall protection for operators working on elevated platforms where overhead fall protection is essential for safe work execution.

At Safetylyne, we specialise in providing cutting-edge overhead rail systems designed to ensure maximum height safety for various applications. Our comprehensive services include the design, installation, and certification of customised overhead rail and davit systems, tailored to meet the specific needs of your industry.

Why Safetylyne Overhead Rail Systems Are the Smart Choice

Safetylyne offers the exclusive Tri-Rail Overhead System, a game-changing solution that supports up to three maintenance personnel simultaneously - delivering safety, efficiency, and innovation you won’t find anywhere else.

Our expert teams across Australia - serving Melbourne, Sydney, Brisbane, and beyond - ensure every system is designed to meet the highest standards, providing peace of mind for even the most complex projects. With a 10-year product and installation warranty and a reputation for quality and compliance, Safetylyne systems are built to perform and endure.

These systems are suitable for large-scale maintenance access requirements, including Boeing aircraft and Boeing Dreamliner, as well as E-Jets, Bombardier planes, sea planes and helicopters.

Features of Our Overhead Rail Systems:

- Full Compliance. Adheres to all relevant Australian standards.

- Minimal Deflection. Ensures minimal movement during a fall, enhancing safety.

- Versatile Applications. Suitable for fall arrest and abseil (rope access).

- Uninterrupted Movement. Allows multiple workers to move freely and safely.

- High-Quality Materials. Manufactured in Australia using high-grade aluminium and stainless steel.

- Flexible Mounting Options. Can be mounted on various surfaces, including purlins, metal or concrete decks, ceilings, and walls.

- Aesthetic and Durable. Neat, unobtrusive design with optional powder coating.

Overhead Rail Safety Systems

Our overhead rail systems feature high-strength, lightweight aluminium rails that can span up to 6 meters between structural supports. These systems include robust sealed bearing trolleys with lateral stabilising bearings, allowing effortless movement for multiple users simultaneously. Complying with AS/NZS1891.2:2001 and AS/NZS1891.4:2009 standards, our locally manufactured systems ensure top-notch safety and reliability.

Overhead Rail Systems for Fall Arrest

Our overhead rail fall arrest systems provide effective, unrestricted fall protection for multiple users working above a designated zone. When used with an inertial reel or retracting lifeline, these systems maintain the user in a fall restraint position, reducing the risk of mid-air suspension. These rails can be mounted to various surfaces, ensuring compliant height safety where other systems might be impractical.

Problem-Solving Applications of Overhead Rail Systems

- Airplane Maintenance

Ensuring compliance with height safety regulations, our overhead rail systems provide secure access from above, which is essential for the maintenance, cleaning, and upkeep of aircraft. These systems allow workers to remain secure even on uneven surfaces at height.

- Mining

In the mining industry, our overhead rails offer safe and efficient access for equipment maintenance and operational inspections, and height access above machinery and elevated areas access, addressing the unique challenges of working in such environments. Overhead rail can solve various height safety in mining.

- Large Vehicle Wash Platforms

For the maintenance and cleaning of large vehicles, our overhead rail systems provide secure and unrestricted access, enhancing both safety and efficiency. Suitable for track wash and maintenance bays.

Potential Access for Overhead Rail Use:

- Food manufacturing and Overhead rail system for meat processing.

- Construction Sites. Provides safe access for workers during high-rise building projects.

- Warehouse Maintenance. Ensures safety for tasks performed at height, such as lighting maintenance and inventory management.

- Manufacturing Facilities. Facilitates safe access to elevated machinery and equipment for maintenance and inspections.

- Building Facades and Canopies. Enables easy access for cleaning and maintenance of building exteriors and canopies.

Additional Features

Our Overhead Rail Systems enable staff who maintain equipment and machinery at height to move freely and safely without the risk of falling or injuring people below. These systems can be installed on a wide variety of structures, ensuring continuous and effective fall protection for multiple workers at once.

Users can travel from a vertical to a horizontal position on one continuous system without disconnecting, enhancing productivity and work at heights safety.

The system is designed for minimal intrusion into the workspace and can bear high loads, making it suitable for various applications.

Floors remain clear of both personnel and equipment, improving safety and efficiency. If you’re not sure if this application suits your needs, give us a call, and we can tailor a solution for you.

The Tri-Rail Fall Restraint System is a proprietary fall arrest and rope access solution specifically designed for environments where consistent fall protection is essential.

This system is particularly well-suited for extended work areas, offering large spanning capabilities that ensure continuous and secure attachment for harness connections. With its rigid rails, the system provides uninterrupted mobility, allowing multiple operators to work simultaneously and efficiently on tasks such as facade access, atrium maintenance, aircraft wing maintenance, fuselage repairs, tail cleaning, and cockpit inspections. By enabling multiple personnel to work on different sections of an aircraft at the same time, this system significantly reduces maintenance time, ensuring faster turnaround and greater operational efficiency.

One of the standout features of our tri-rail system is its ability to accommodate complex architectural designs, including building corners and irregular curves.

Manufactured from marine-grade aluminium and 304 stainless steel, the system is both lightweight and corrosion-resistant, making it ideal for use in highly corrosive environments. Additionally, with a 25-year materials warranty and a 2-year installation warranty, the Tri-Rail System offers long-term reliability and peace of mind. This makes it a robust choice for industries ranging from mining to large-scale vehicle maintenance and more.

For specialised applications in the aviation industry, including bespoke solutions for aircraft maintenance, visit our Aviation Access Systems page to explore a range of innovative systems designed for safe and efficient maintenance access.

Contact our friendly team today for more information on our overhead rail systems, to get a consultation.

Let Safetylyne be your trusted partner in ensuring the highest standards of height safety for your operations.

Industry information - Civil Aviation Safety Authority