Access Ladders

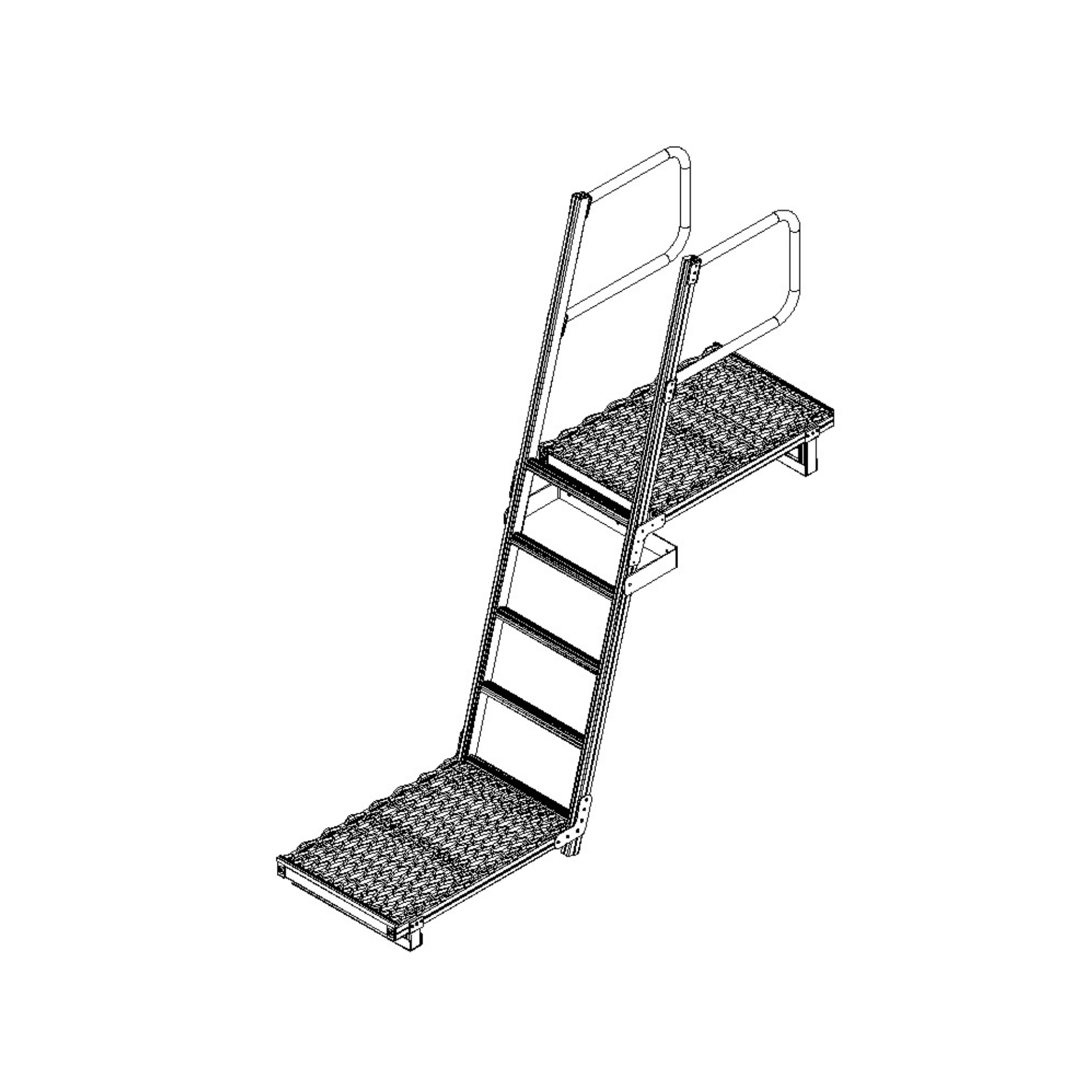

The Safetylyne Access Ladder system has been developed and engineered to provide an adaptable, modular solution for ladder access between service areas for internal and external uses.

Constructed of structural grade aluminium extrusions designed to increase grip ratings and ladder spans, providing a cutting-edge solution which complies with AS 1657.

Comparing Angled Ladders and Vertical Ladders

Angled Ladders

Angled ladders are a traditional choice for accessing elevated areas in various industrial and commercial settings. These ladders are securely attached to the structure at a fixed angle, typically ranging from 60 to 75 degrees. One of the key advantages of angled ladders is their simplicity and ease of installation. They are often preferred when space constraints or structural limitations make other options impractical.

Vertical Ladders

Vertical leaders often equipped with fall arrest systems, offer a different approach to height safety. Instead of a traditional ladder structure, vertical aluminium ladders consist of a cable or rail system that runs alongside the climbing path. Workers use a harness and lanyard to attach themselves to the line, providing continuous fall protection as they ascend or descend.

The primary advantage of vertical step ladders is their versatility and adaptability to various structures and environments. They can be installed on buildings, towers, and other elevated structures, offering reliable fall protection without the need for a traditional ladder structure. Vertical ladders are particularly well-suited for situations where space is limited or where regular ladder use may not be practical.

Choosing the Right Solution

When deciding between angled ladders and vertical ladders, several factors should be considered:

+ Space and Structure

Evaluate the available space and the structure of the building or facility where the height safety system will be installed. Angled ladders may be more suitable for structures with ample space and clear access points, while vertical ladders offer greater flexibility in tight or unconventional spaces.

+ Usage and Frequency

Consider how often the height safety system will be used and the specific tasks it will be used for. angled ladders are ideal for frequent access to elevated areas, while vertical ladders are better suited for infrequent access requirements.

+ Compliance and Regulations

Ensure that the chosen height safety solution complies with relevant safety regulations and standards in your jurisdiction.

At Safetylyne, we ensure that all of our access ladders are manufactured to the highest standards, using durable materials and robust construction techniques. Our ladders are designed to withstand heavy use and harsh environmental conditions.

With over two decades of expertise in height safety systems, we are dedicated to providing reliable solutions that keep workers safe and secure.

Custom Access Ladder Solutions for All Industries

We specialise in designing, manufacturing, installation and certifcation of custom access ladders tailored to the specific needs of your facility.

Whether you require vertical ladders, folding ladders, caged access ladders, ladders with platforms and other kinds of step ladders for safe access - our solutions are compliant with Australian height safety standards and engineered to provide long-lasting performance in a variety of environments. From industrial and infrastructure settings to commercial buildings, our bespoke access ladders are suitable for maintenance access, roof access, and HVAC plant platforms access solutions, ensuring safe and efficient movement in challenging spaces.

Our access ladders are crafted from high-quality aluminium, designed to withstand harsh weather conditions and provide corrosion resistance, making them ideal for outdoor use, including coastal environments.

With anti-slip rungs and options for handrails and safety cages, we ensure your maintenance personnel can work safely at heights. We also offer modular ladder systems that can be tailored to fit complex access requirements, such as HVAC units, warehouses, construction sites, plant room maintenance access etc.

Understanding the Differences: Caged Ladders & Line Ladder Systems

CAGED LADDERS

Caged ladders have long been a staple in various industries for providing safe access to elevated areas such as rooftops, platforms, and mezzanines. These ladders are characterised by their enclosures, typically made of steel, surrounding the climbing rungs. The primary purpose of the cage is to prevent falls and provide a secure pathway for ascending and descending.

In line with AS1657:2018 standards, Caged ladders must adhere to specific design and installation requirements to ensure optimal safety. These include appropriate ladder pitch, rung spacing, cage dimensions, and anchorage to a structure capable of withstanding the applied loads. The cage itself must also meet dimensional standards to allow for safe ingress and egress.

One of the key advantages of caged ladders is their inherent stability and reliability. The cage provides a physical barrier that helps to prevent slips and falls, especially in adverse weather conditions or when carrying equipment. Additionally, the cage serves as a visual indicator, making the ladder easily identifiable and promoting compliance with safety protocols.

LINE LADDERS

These systems feature a vertical lifeline that runs alongside the ladder, providing continuous fall protection for the user. The lifeline is typically attached to an overhead anchorage point and incorporates a sliding mechanism that moves with the user as they ascend or descend the ladder.

AS1657:2018 standards outline specific requirements for line ladder systems, including the design and installation of the vertical lifeline, anchorage points, and ladder structure. It is essential for these systems to undergo regular inspection and maintenance to ensure their integrity and functionality.

One of the primary benefits of line ladder systems is their versatility and adaptability to various environments.

Unlike caged ladders, which require a dedicated enclosure, line systems can be installed on existing ladder structures, minimising the need for extensive modifications.

Additionally, the continuous fall protection offered by the vertical lifeline enhances worker safety, particularly in high-risk scenarios like work at heights.

Choosing the Right System

When determining whether to implement a caged ladder or a line ladder system, several factors must be considered, including the specific application, environmental conditions, regulatory requirements, and user preferences. Both systems have their unique strengths and limitations, and the decision should be based on a thorough risk assessment and consultation with height safety experts.

At Safetylyne, we understand the importance of selecting the right height safety system to mitigate risks and protect workers.

The Safetylyne Way

At Safetylyne, we are dedicated to developing cutting-edge roof safety and maintenance access solutions tailored to our clients' evolving needs. As your trusted partner, we offer specialised insights into proprietary engineered systems and custom access solutions, simplifying the complexities surrounding access solutions. Contact the Safetylyne team, experts in height safety, today to explore tailored solutions for your height safety and maintenance access needs.

Reach out to us at info@safetylyne.com.au or call 1-800-666-686

Rung Ladders and Step Widths:

Compliance with Australian Regulations

Rung stairs, often referred to as ladder stairs, are designed for steep or vertical access, typically found in industrial or maintenance environments where space is limited.

These stairs feature cylindrical or flat rungs rather than traditional steps, and they are used for short-term access or infrequent use, such as in areas where only maintenance workers need to access equipment or rooftops.

Step Widths and Australian Standards

In Australia, the

width and design of steps or rungs are regulated to ensure safety.

Guidelines for Access Stairs:

- Minimum Step Width

According to AS 1657, the standard governing fixed platforms, walkways, stairways, and ladders, access stairs must have a minimum width of 600mm for standard stairways. However, wider steps are often used in high-traffic areas to accommodate multiple users and improve safety.

- Rung Width for Ladders

Rung stairs or ladders require rungs that are at least 400mm wide to provide sufficient stability and support. The spacing between rungs should typically range between 230mm and 300mm to allow safe and comfortable climbing.

- Tread Depth and Angle

For standard stairs, the tread depth is recommended to be not less than 185mm.

The angle of inclination for stairs generally ranges between 30° and 50°, depending on the type of access required and frequency of use. For rung stairs or steep access, inclinations closer to 60° or even vertical angles may be permitted, provided that proper safety systems, such as handrails or safety cages, are in place.

These regulations ensure that both rung stairs and traditional access stairs provide safe and reliable access to elevated or hard-to-reach areas, supporting the safety of workers in industrial, maintenance, and construction environments.

Nationwide Installation and Compliance

As a trusted provider of access systems across Australia, Safetylyne offers nationwide installation of access ladders, with a quick turnaround to ensure your projects remain on schedule. Whether you're located in Sydney, Brisbane, Melbourne, Adelaide, Cairns, and other locations in Australia, our experienced team provides on-site assessments, ensuring that each step ladder is perfectly fitted and meets the safety requirements of your facility.

Our ladders are designed to comply with Australian Standards AS1657, providing you with peace of mind that your site is equipped with the safest and most reliable access solutions available.

Our commitment to delivering customised access solutions goes beyond just ladders. We integrate our ladders with roof walkways, guardrails, and platforms to provide comprehensive access systems that enhance safety and efficiency across your entire facility.

Whether you need access solutions for factories, warehouses, airports, or government facilities, Safetylyne’s ladders offer the durability and functionality needed to keep your operations running smoothly.