ROOF SAFETY REGULATIONS Explained

Roof Safety Regulations in Australia

Roof safety in Australia encompasses the regulations, standards, practices, and technologies employed to ensure the safety of individuals working on or accessing roofs. Given the country's diverse climates and the variety of building types, roof safety is a critical concern for both commercial and industrial properties.

Overview

Roof safety involves implementing measures to prevent falls and injuries for workers performing maintenance, inspections, installations, or other activities on rooftops. The Australian government and various industry bodies have established stringent standards and guidelines to mitigate risks associated with working at heights.

Regulatory Framework

Australia's roof safety regulations are governed by the Work Health and Safety (WHS) laws, which are enforced at both federal and state levels. The key regulatory bodies include:

- Safe Work Australia: Develops national policy and guidance for workplace safety, including working at heights.

- State Work Health and Safety Authorities: Enforce compliance with WHS laws within their respective jurisdictions.

Key Standards and Guidelines

Several standards and guidelines underpin roof safety practices in Australia:

- AS/NZS 1891.4:2009: Industrial fall-arrest systems and devices. Part 4: Selection, use, and maintenance.

- AS/NZS 5532:2013: Manufacturing requirements for single-point anchor devices used for harness-based work at height.

- AS/NZS 4488.1:1997: Industrial rope access systems. Part 1: Specifications.

- AS 1657:2018: Fixed platforms, walkways, stairways and ladders — Design, construction and installation.

- Safe Work Australia Code of Practice: Provides practical guidance on managing risks associated with working at heights. See Safe Work Australia Information Sheets here.

Australian Standards for Steps, Stairs & Ladders

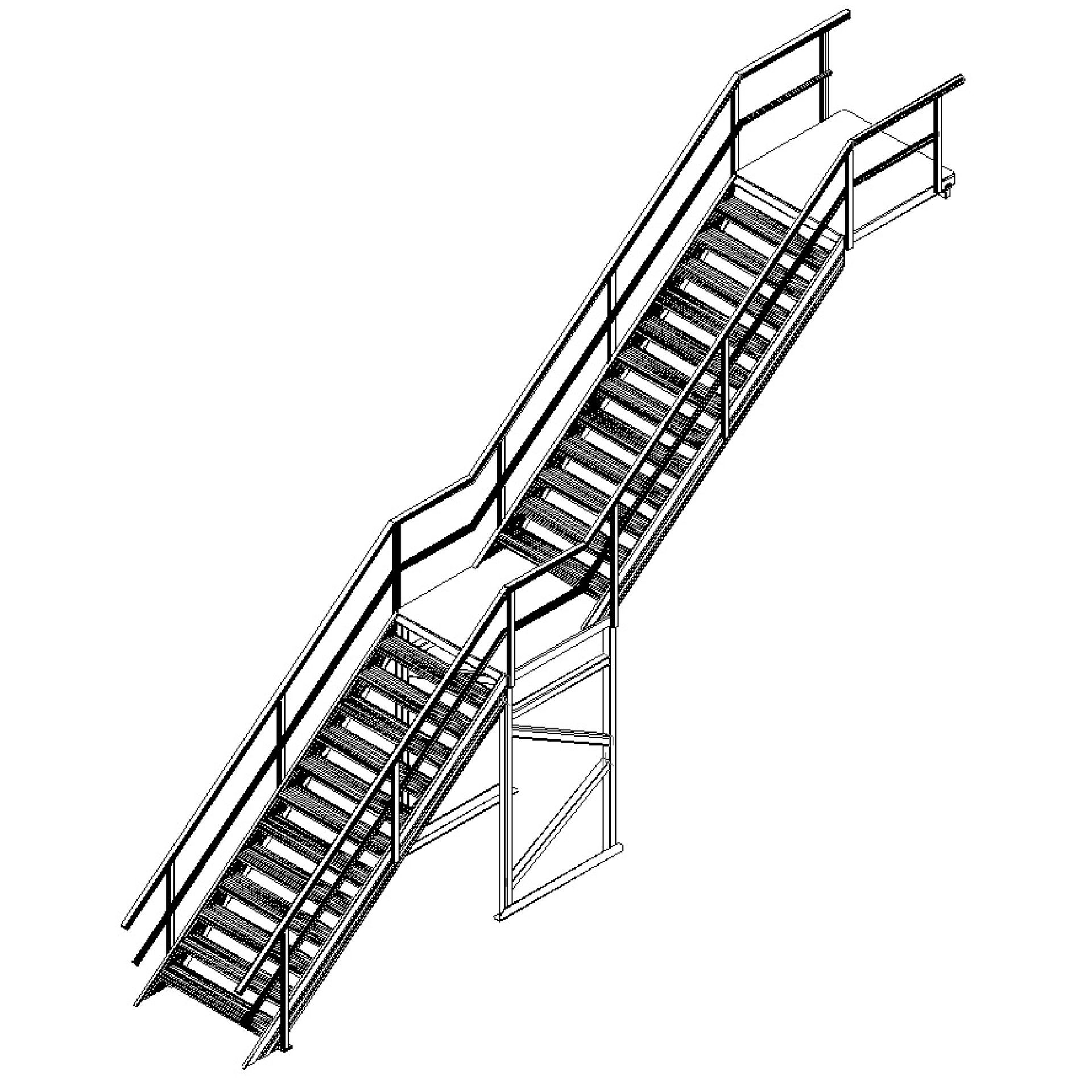

In Australia, access systems such as steps, stairways, and ladders must comply with AS 1657, which outlines the minimum requirements for safe design, construction, and installation.

This includes specifications for:

- Selection of correct access means for the application

- Design criteria

- Tread depth and riser height

- Material and spacing dimensions

- Slope and angle of stairways

- Handrail dimensions and placement

- Clearance, landing, and access requirements for fixed ladders

Compliance with these standards helps reduce the risk of falls and ensures safe, consistent access across industrial and commercial environments.

Safety Systems

Effective roof safety measures include a combination of systems and equipment designed to prevent falls and ensure the safety of workers. Key components include:

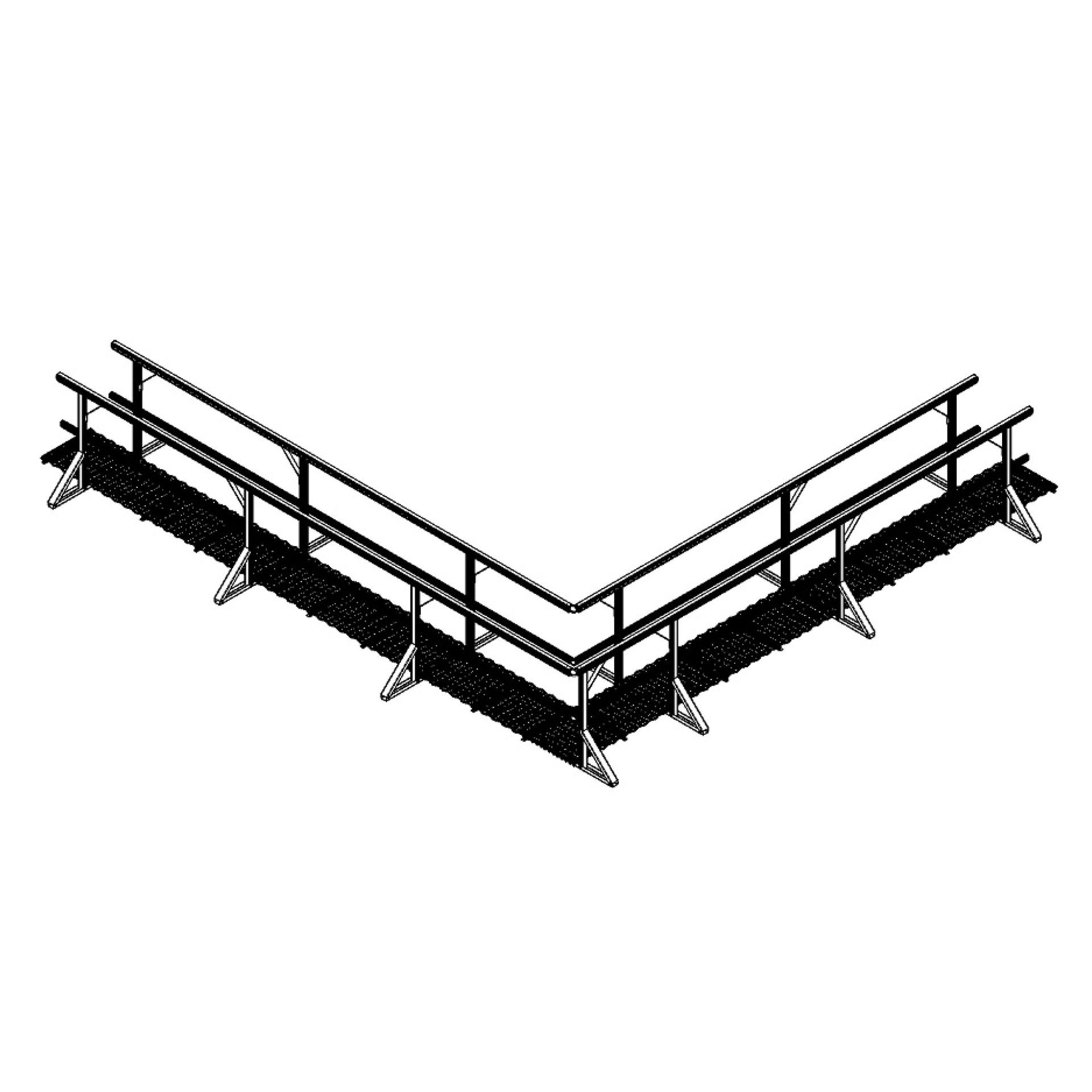

+ Guardrails

Provide a physical barrier to prevent falls from edges and openings.

+ Anchor Points

Secure attachment points for fall restraint/arrest systems.

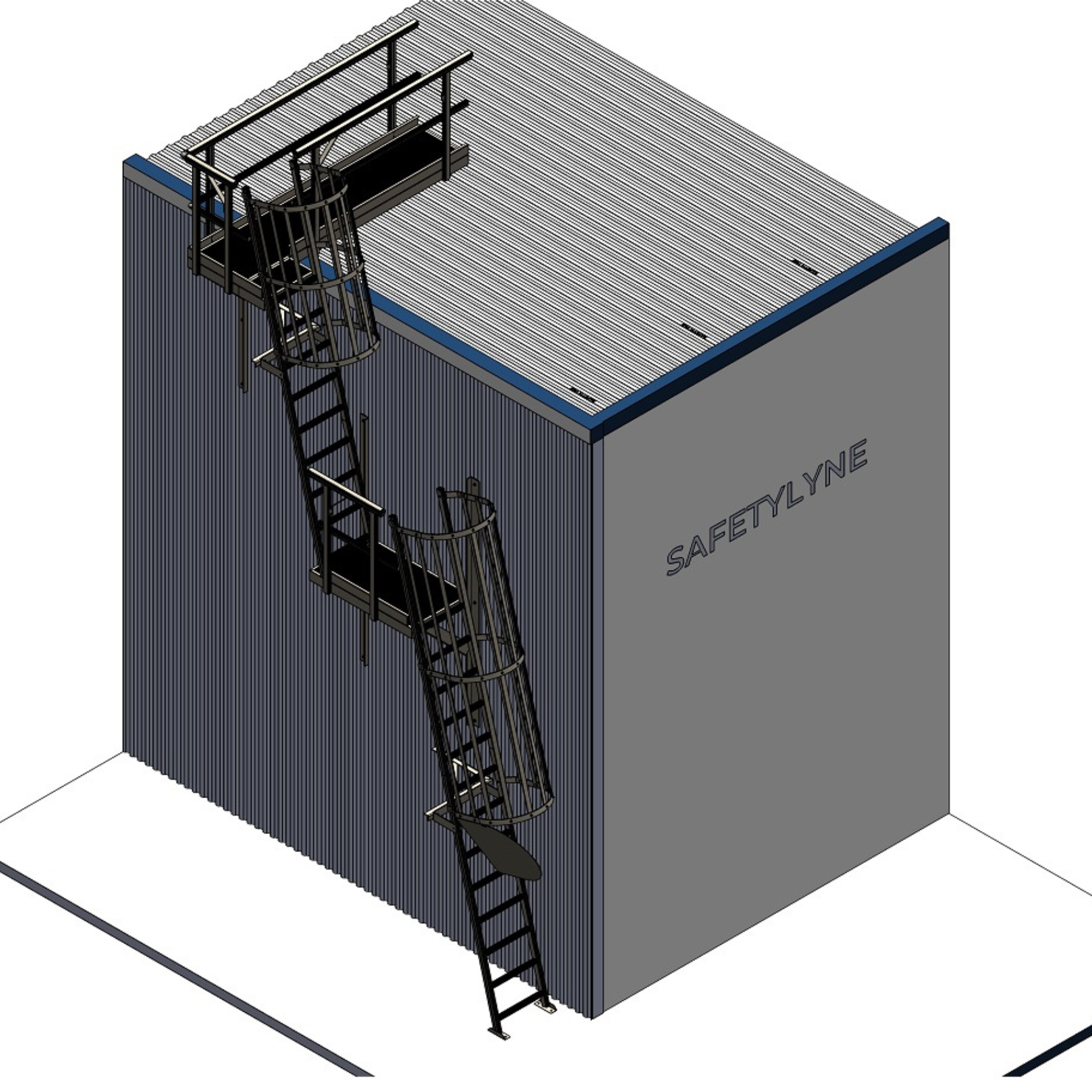

+ Ladder AND STAIRS Systems

Secure access systems that prevent falls while ascending or descending.

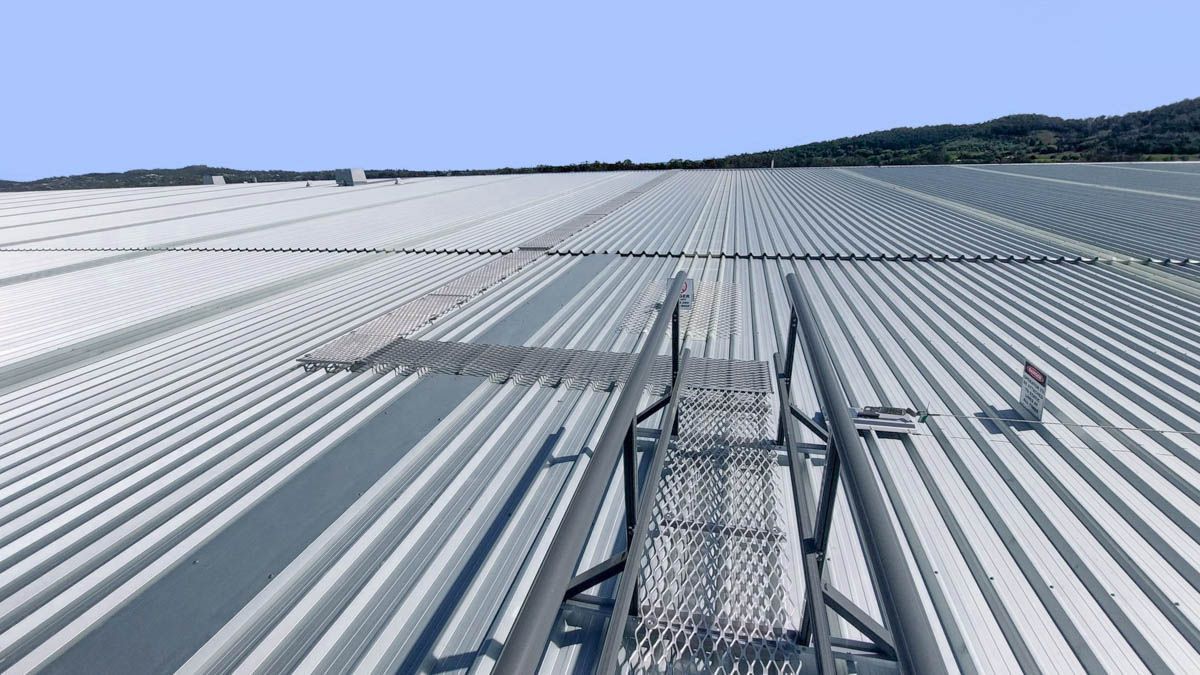

+ Roof Walk ways

Provide safe and stable surfaces for workers to move around on rooftops.

+ PLANT DECKS AND PLATFORMS

Plant decks enhance safety by providing stable, non-slip surfaces for equipment access and maintenance, making them essential for roof safety and compliance with height safety regulations.

Industry Practices

Roof safety in Australia also involves regular inspections and maintenance to ensure that all safety systems and equipment remain effective. Key practices include:

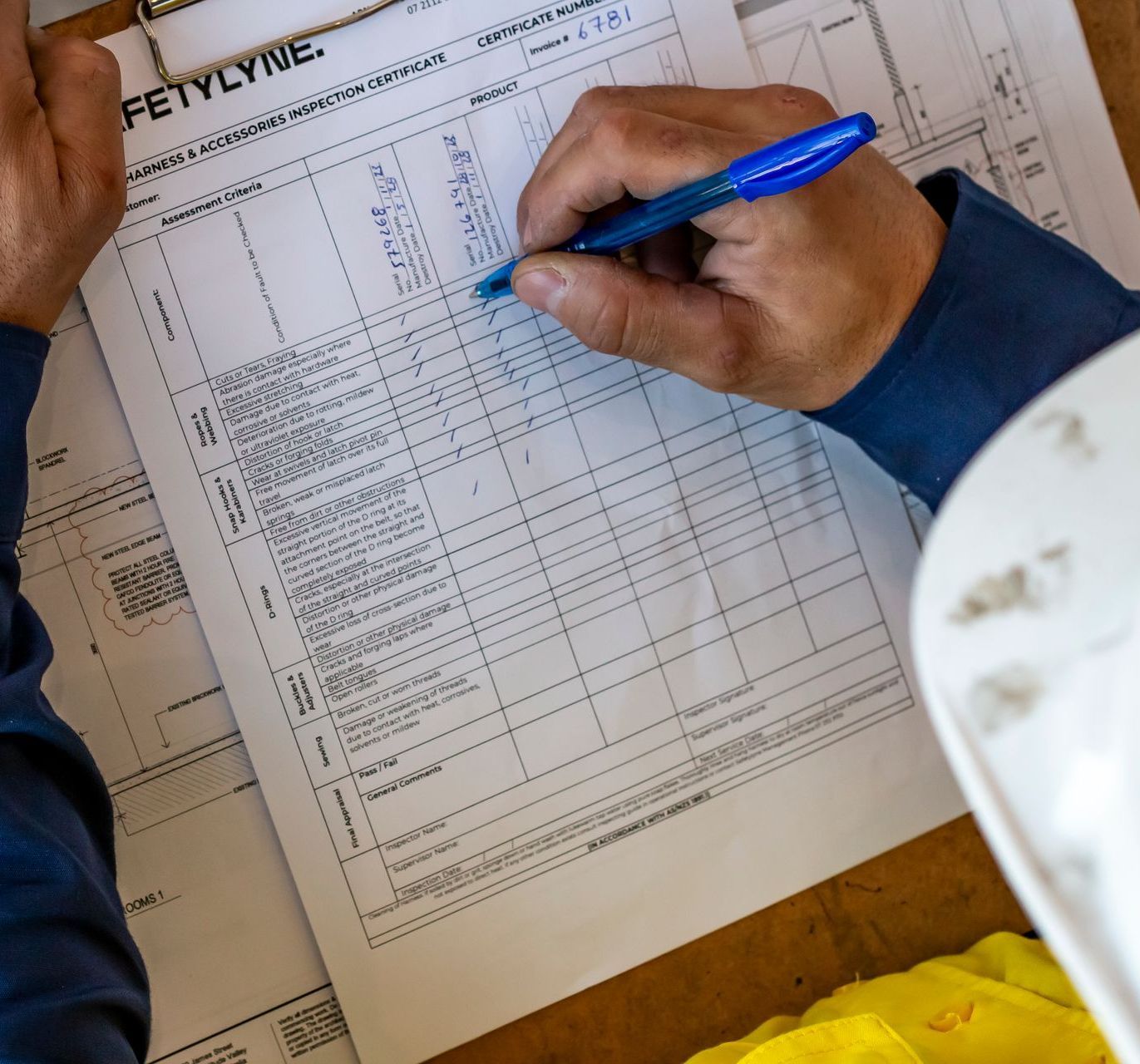

- Routine Inspections. Regular checks of anchor points, guardrails, and other safety systems.

- Maintenance Programmes. Scheduled maintenance to repair and replace worn or damaged components.

- Documentation and Compliance. Keeping detailed records of inspections, maintenance, and worker training to comply with WHS regulations.

Roof Safety Inspection and Recertification:

A Mandatory Requirement in Australia

Roof safety recertification is a mandatory requirement in Australia. Under the Work Health and Safety (WHS) regulations, regular inspections, maintenance, and recertification of fall protection systems, including roof safety systems, are essential to ensure they remain in good working condition and compliant with safety standards.

The required frequency for inspecting roof safety systems varies by state and territory:

- Australian Capital Territory (ACT), Northern Territory (NT), Queensland (QLD), South Australia (SA), Victoria (VIC), and Western Australia (WA): Inspections are mandated every 6 months.

- New South Wales (NSW): Inspections are required every 12 months.

This includes vital components such as anchor points, static lines, and guardrails.

Regular recertification maintains compliance and helps to identify any potential issues, wear and tear that could compromise the safety of the system.

By adhering to these regulations, businesses can minimize risk exposure, ensure the safety of individuals working at heights and maintain a safe working environment.

Complying with Roof Safety Regulations Without Compromising Aesthetics

A common concern when installing roof safety systems is the potential impact on a building's architectural design and aesthetic. However, compliance with roof safety regulations doesn't have to come at the expense of your building's appearance.

At Safetylyne, we specialise in custom solutions that address both safety and design. For example, our collapsible guardrails remain hidden when not in use, folding away to maintain the building's aesthetics and only erected when needed for maintenance or safety purposes. We also offer safety systems in a variety of colours, ensuring that stairs, guardrails, and platforms blend seamlessly with the building's aesthetic.

Roof Platforms with HVAC screens not only enhance safety but are designed to conceal equipment, improving the overall look of your building. Whether you need roof access systems, plant decks, or solutions for facade maintenance access, Safetylyne provides innovative options that balance safety, compliance, and visual appeal.

Useful Resources for Height and Roof Safety Regulations in Australia

Ensuring compliance with height and roof safety regulations is crucial for workplace safety. Here are some key resources to help you stay informed and compliant:

Safe Work Australia website, Codes of Practice and relevant Australian Standards.

Safe Work Australia is the national policy body responsible for developing model work health and safety laws. They provide guidelines and resources for height safety.

State and Territory Regulators

- WorkCover QLD: WorkSafe Queensland

- SafeWork SA: SafeWork South Australia

- WorkCover NSW: SafeWork New South Wales

- WorkSafe VIC: WorkSafe Victoria

- WorkSafe WA: WorkSafe Western Australia

- WorkSafe NT: WorkSafe Northern Territory

- WorkCover TAS: WorkSafe Tasmania

- WorkSafe ACT: WorkSafe Australian Capital Territory

At Safetylyne, we can assist in achieving compliance through the installation of permanent height safety systems, development of safe access strategies, audits and certification of existing systems. For more information about workplace height safety and compliance, please refer to the relevant government regulators listed above.

Differences Between NSW and QLD Height Safety Regulations

Understanding the specific height safety regulations in New South Wales (NSW) and Queensland (QLD) is crucial for ensuring compliance and safety in construction and other high-risk industries.

NSW Height Safety Regulations

1. General Requirements

The NSW regulations, under Part 4.4 of the WHS Regulation 2017, cover various scenarios involving fall hazards such as elevated workplaces, edges, openings, and fragile surfaces.

2. Hierarchy of Controls

NSW enforces a strict hierarchy of controls to mitigate fall risks. This hierarchy begins with the elimination of hazards, followed by using fall prevention solutions(like guardrails), work positioning systems such as fall restraint/arrest systems.

3. Safe Work Method Statements (SWMS)

For any construction activity where there is a risk of falling more than two meters, NSW mandates the preparation and implementation of a SWMS to document and follow all safety protocols during the work.

QLD Height Safety Regulations

- Height Thresholds

Queensland has specific thresholds for implementing safety measures. Fall prevention is mandatory for heights of three meters or more, while for general construction, the threshold is two meters.

2. Control Measures

The regulations require robust fall prevention controls, such as edge protection for significant height risks. If these measures are unsuitable, fall arrest systems must be employed.

3. Detailed Provisions

QLD height safety regulations provide detailed guidance on various fall protection systems, including edge protection, fall protection covers, travel restraint systems, fall arrest platforms, harnesses equipment and safety nets. These additional requirements ensure comprehensive safety measures are in place.

While both states adhere to the harmonised WHS regulations, the specific requirements and thresholds for fall prevention measures vary, with Queensland having more detailed and stringent regulations in certain scenarios.

Height Safety Regulations in South Australia

Height Safety regulations in SA are slightly different from other states.

It's crucial to note that inspection intervals can vary across different Australian states and territories. For instance, while South Australia enforces a 6 month inspection schedule, New South Wales requires inspections every 12 months. These differences highlight the importance of adhering to local regulations to maintain compliance and ensure safety.

Learn everything you need to know about SA roof safety here.

For insights into how Australia’s roof safety regulations compare to those in the US and Europe, check out our blog: Roof Safety Regulations: Australia vs. the Rest of the World.

Safetylyne Way

With 25 years of industry experience, Safetylyne provides a full range of roof safety solutions, including design, fabrication, manufacture, installation, and maintenance. The company is known for its NATA-certified and engineered systems with ultimate commitment to quality and safety.

Specialising in custom-engineered systems, Safetylyne ensures compliance with stringent Australian safety standards and regulatory guidelines. Our innovative fall prevention solutions include staticline systems, anchor points, platforms, stairs, gantries and rail systems designed for various industries such as construction, food manufacturing facilities, HVAC, abattoirs, horticulture, mining, large solar panels units maintenance and other industries.

Talk to HEIGHT Safety Experts

Let's discuss your project