Pipelines ACCESS

Systems

Essential Insights for Safety and Efficiency

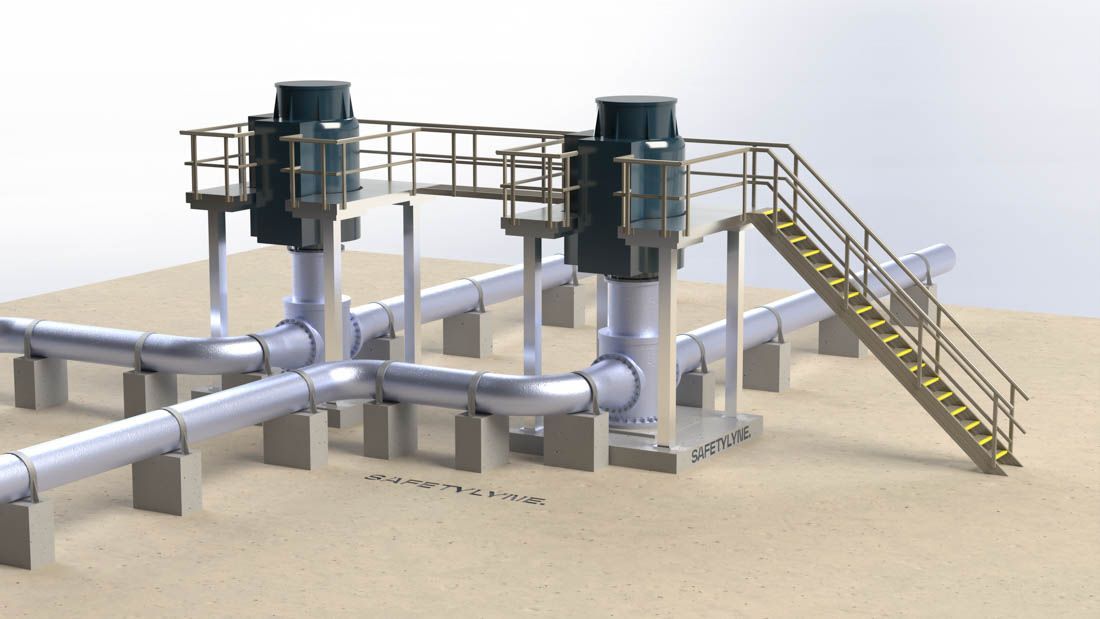

Pipelines play a vital role in transporting liquids, gases, and resources essential to industries worldwide. From oil and gas to water treatment and resource management, pipelines enable the seamless movement of materials over vast distances. However, maintaining their integrity and functionality requires safe, durable, and efficient access systems.

Pipeline Maintenance Matters

Pipelines are lifelines of modern infrastructure, but they are not immune to wear and tear. Regular maintenance, including cleaning, testing, and replacing worn parts, is critical to:

- Extending lifespan: Proactive care ensures pipelines remain functional and reliable for years.

- Preventing failures: Pipeline failures can cause spills, leaks, and damage to nearby infrastructure like roads, bridges, and buildings.

- Reducing risks: Well-maintained pipelines are less likely to experience costly disruptions or environmental hazards.

By addressing maintenance needs promptly, operators safeguard their investments and protect surrounding communities.

Challenges in Pipeline Maintenance

Maintaining pipelines is not without its challenges, especially when they span long distances or traverse harsh environments. Key challenges include:

- Difficult access: Pipelines in remote areas or elevated locations require specialised systems to ensure safe and efficient maintenance.

- Harsh conditions: Exposure to weather, chemicals, and heavy loads can degrade materials over time.

- Cost pressures: Maintenance costs are a significant challenge, but efficient access solutions can reduce overall expenses.

To overcome these challenges, investing in

durable, corrosion-resistant materials and

modular access systems is essential.

Solutions for Pipeline Access

Access systems designed for pipelines address these challenges by providing safe and efficient ways to inspect, repair, and maintain infrastructure. Here’s what to look for in an effective pipeline access system:

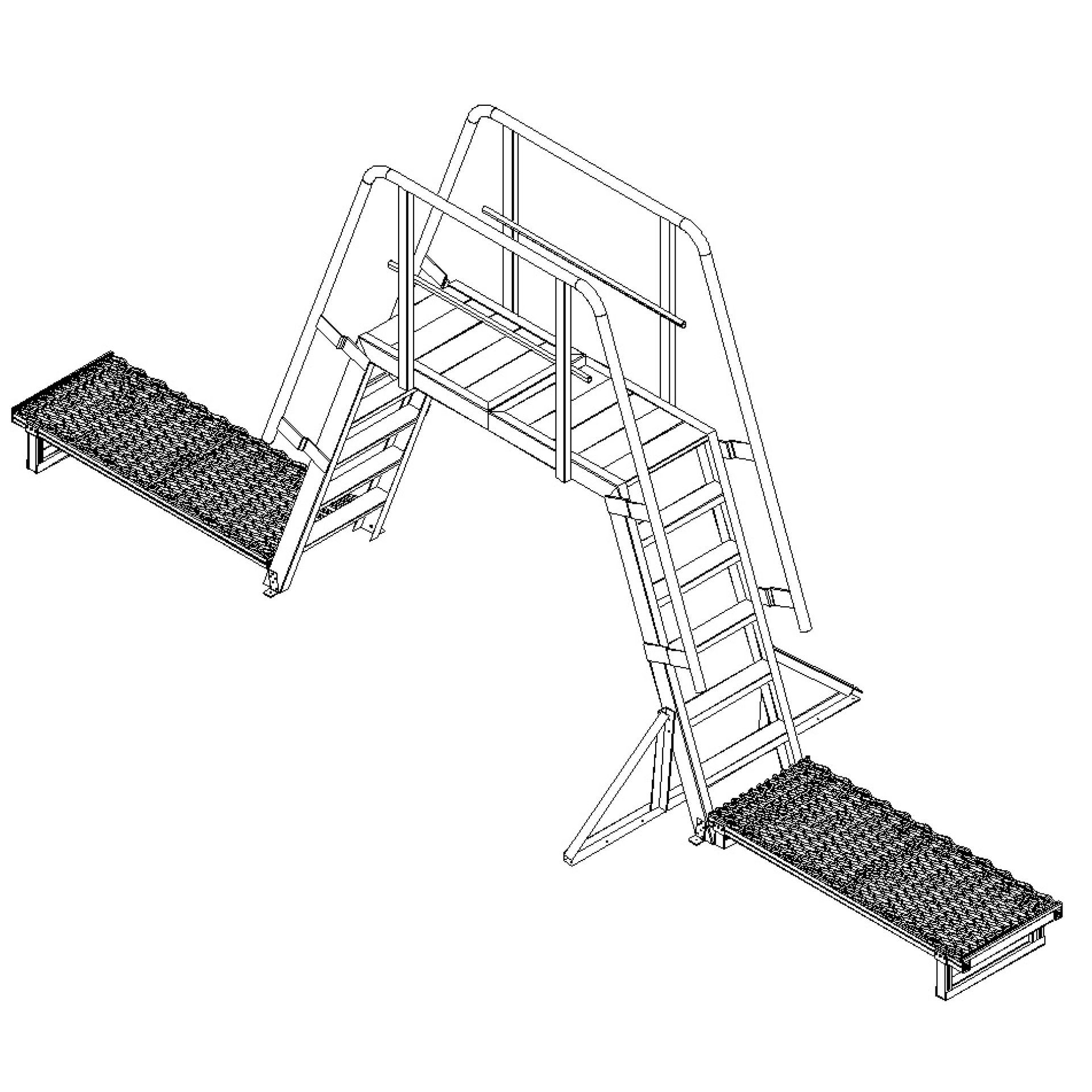

+ Walkways and Crossover Bridges

- Enable unrestricted movement across pipelines.

- Provide safe access points to critical areas.

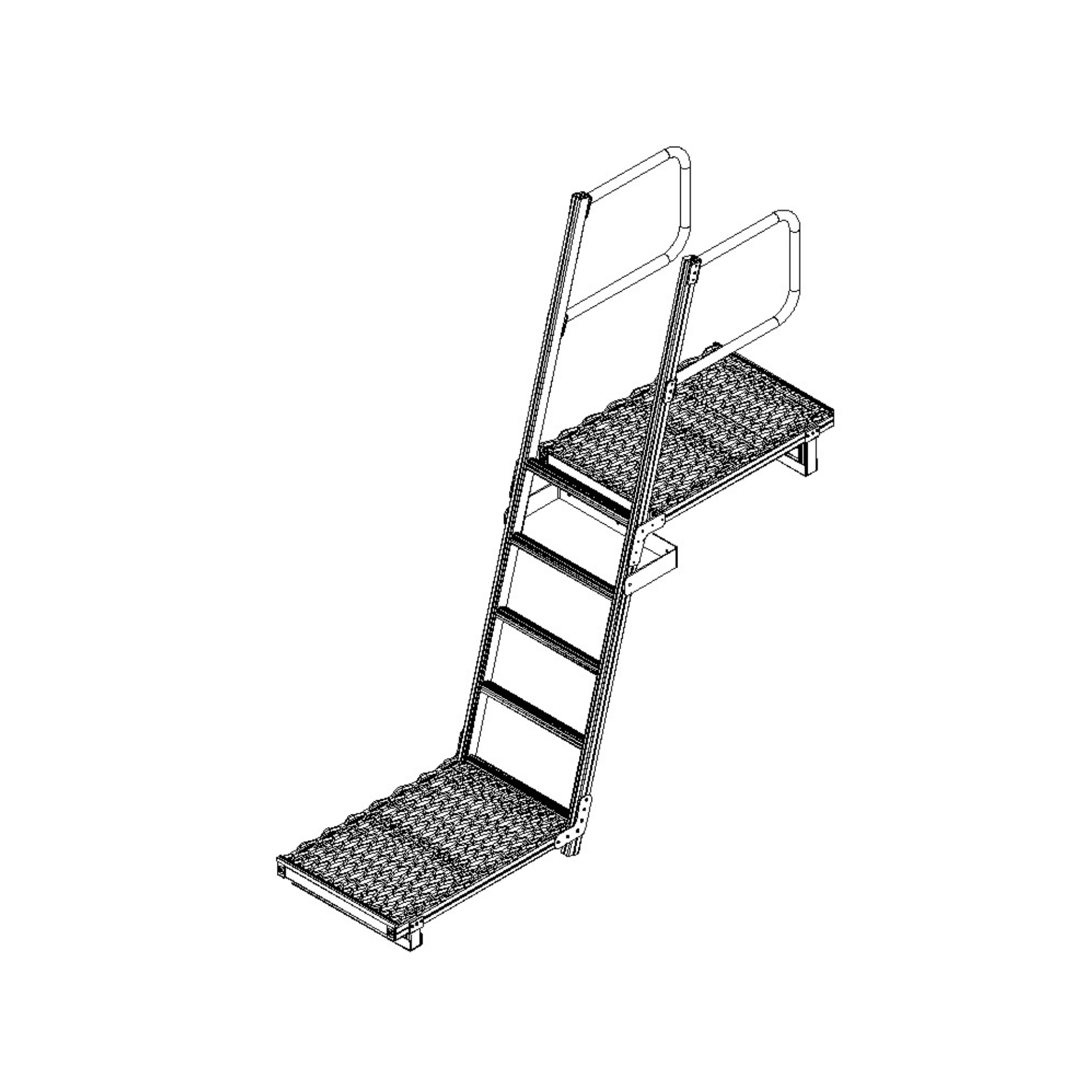

+ Height Safety Features

- Guardrails and ladders ensure workers can access elevated or hard-to-reach areas securely.

+ Durable Materials

- Aluminium is ideal for its lightweight, corrosion resistance, and weatherproof properties.

- Materials must withstand exposure to chemicals, heavy loads, and environmental conditions.

+ Modular Designs

- Adaptable systems that can be customised to fit specific pipeline layouts and future needs.

These solutions not only improve safety but also significantly reduce maintenance costs and resource usage, addressing one of the most pressing industry challenges.

Pipe Safety and Height Safety Regulations in Australia

In Australia, height safety regulations are essential for ensuring the safety of workers performing maintenance, inspections, or installations on pipelines. AS1657, the Australian Standard for fixed platforms, walkways, stairways, and ladders, provides clear guidelines for the design, construction, and installation of access systems.

These standards ensure that all platforms, guardrails, and ladders used in pipeline access are compliant, offering adequate load capacity, slip resistance, and protection against falls.

For pipelines that traverse elevated areas, such as bridges, steep inclines, or industrial facilities, compliance with height safety regulations is critical to minimise risks. Employers are also required under Work Health and Safety (WHS) laws to provide safe working conditions, which include regular inspections and maintenance of access systems. Adhering to these regulations not only protects workers but also reduces operational downtime and liability, fostering a safer and more productive environment.

Consultative Approach for Tailored Access Solutions

We believe every project is unique, which is why our consultants take the time to understand your specific needs. Through comprehensive site audits and appraisals, we identify potential risks and opportunities to:

- Recommend solutions that ensure compliance with Australian standards

- Enhance operational safety and efficiency

- Deliver systems that balance durability and cost-effectiveness

Our collaborative process ensures you receive a solution designed not just to meet regulations, but to exceed expectations

Why Safetylyne Access Systems Are a Smart Choice

With nearly 25 years of experience in height safety, we provide innovative, reliable, and tailored solutions for cooling tower access. From design and fabrication to installation, we ensure your access systems meet the highest standards for safety and performance.

Consultative Approach

Our experienced consultants use a consultative approach to deliver tailored solutions. We conduct audits and site appraisals to assess your needs and recommend the most compliant, durable, and cost-effective systems for your facility.

Contact us today to discuss your cooling tower access needs and create a safer, more efficient workspace.

GOT A QUESTION ABOUT ACCESS SOLUTIONS?

For top-quality, custom-engineered access solutions for your facility, contact Safetylyne today. Our experts are ready to provide comprehensive safety audits, recommendations, and installations to ensure the highest level of safety and efficiency for your operations.

TALK TO HEIGHT SAFETY EXPERTS ABOUT YOUR PROJECT TODAY: