Waste management access solutions

Managing the Work Environment in Waste & Recycling Facilities

Waste and recycling facilities present unique challenges due to heavy machinery, airborne contaminants, hazardous materials, and high-traffic work zones. Proper work environment management is critical for ensuring worker safety, regulatory compliance, and operational efficiency.

By implementing strategic access solutions, environmental controls, and safety procedures, facilities can reduce risks, enhance productivity, and maintain compliance with Australian Standards such as AS/NZS 1657, AS/NZS 4801, and AS/NZS 4994.1.

Key Factors in Managing the Safe Work Environment

Safe Access & Height Safety Solutions

Proper access solutions minimise fall risks, enhance efficiency, and ensure equipment maintenance can be performed safely.

+

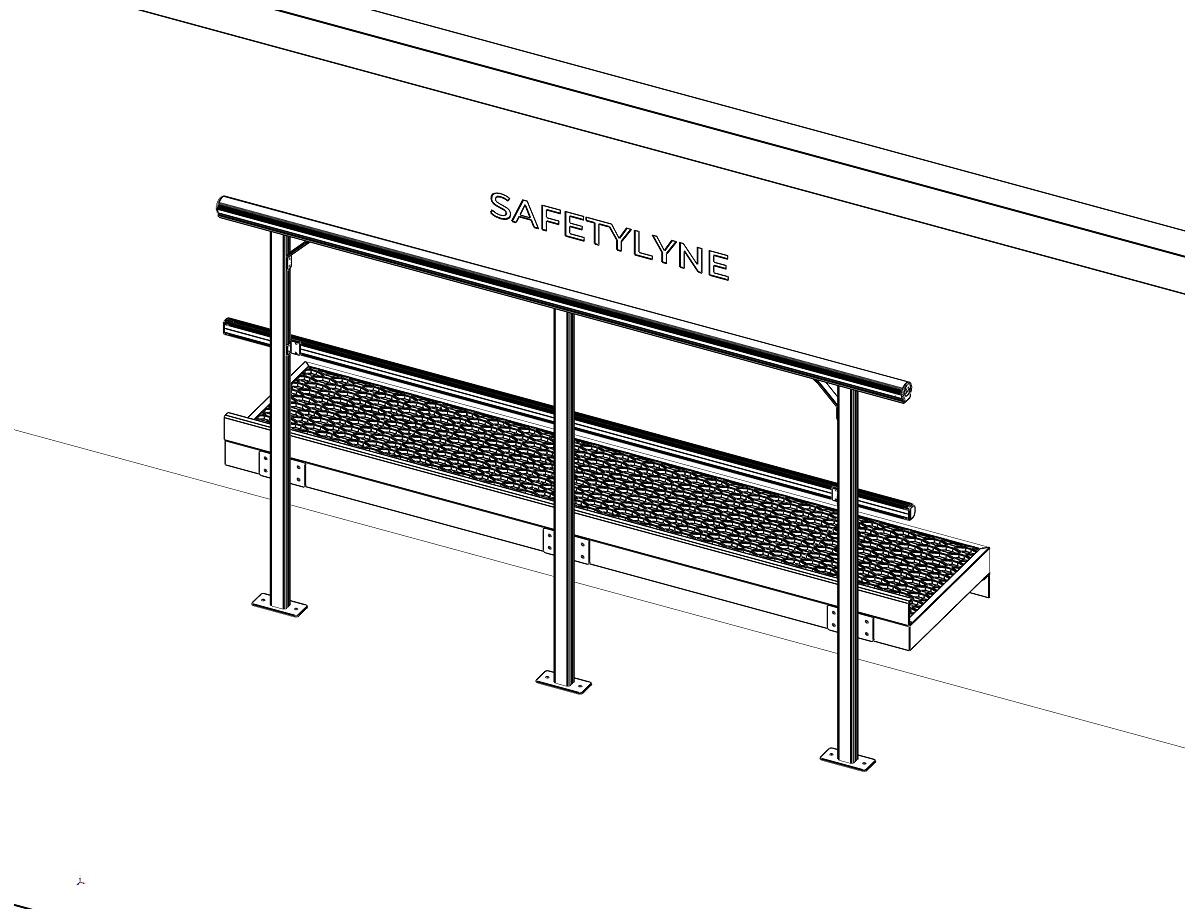

Walkways

&

Gantries – Provide safe movement over processing areas, conveyors, and high-risk zones

+

Non-Slip Walkways & Platforms – Reduce the risk of slips from dust, moisture, and debris

+

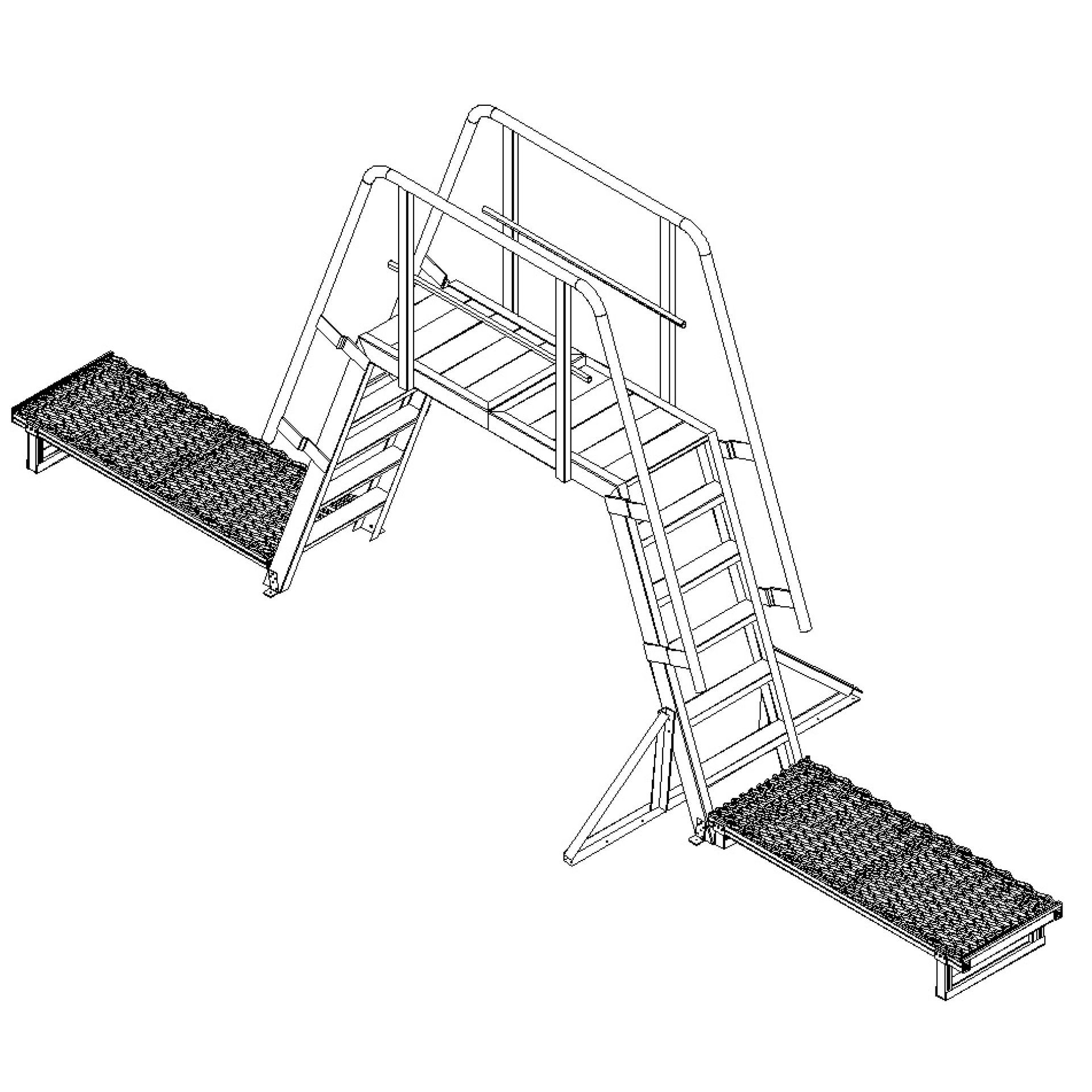

Crossover Bridges – Ensure safe crossing over pipelines, conveyors, and high-traffic areas

+

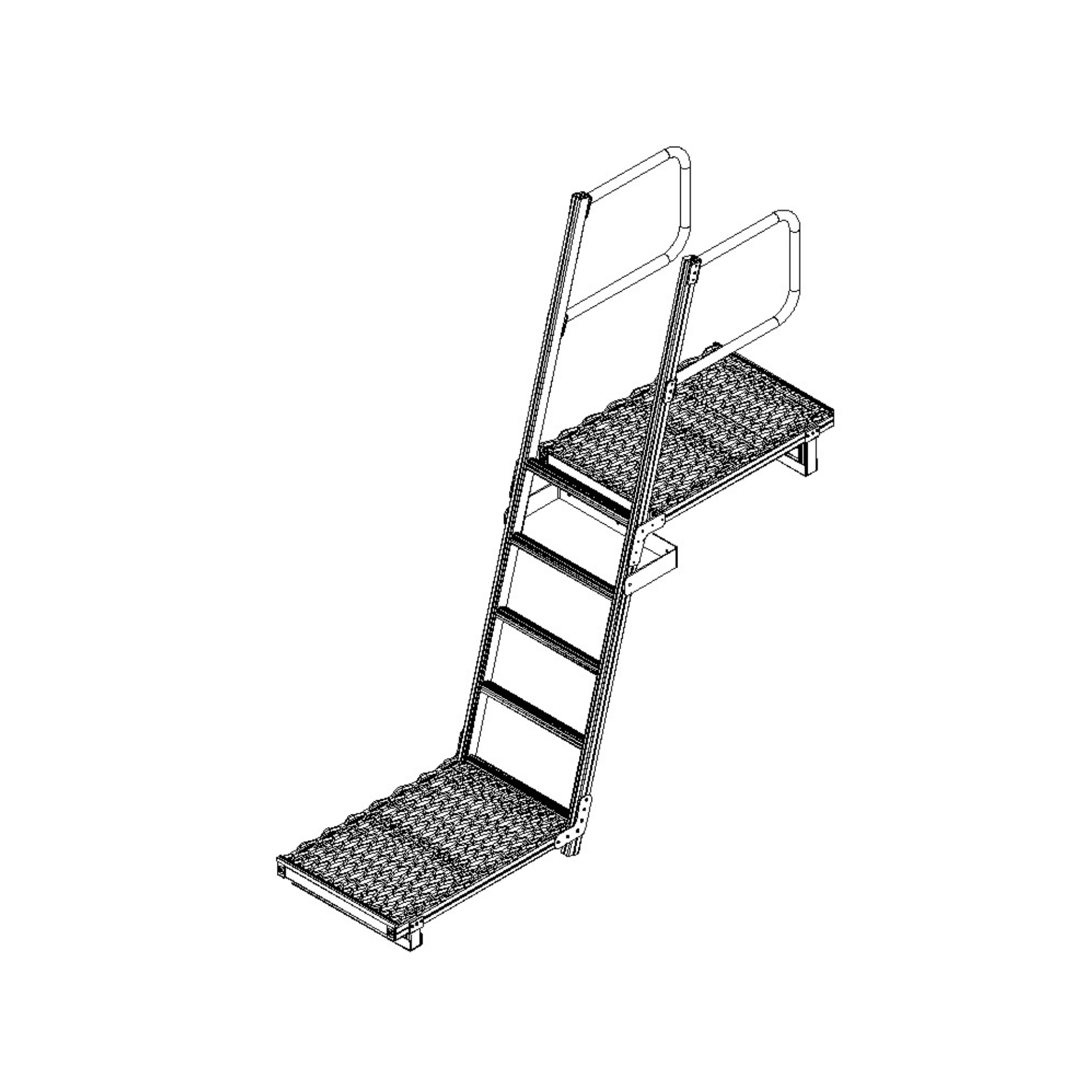

Roof Access Stairs &

Hatches – Provide maintenance access to

HVAC, ventilation, and solar panels

+ Conveyor Access Platforms & Guardrails – Essential for safe inspection and maintenance of conveyor belts, used for sorting and processing recyclable materials.

+ Ladder Systems – Provide safe vertical access to elevated structures, silos, and storage areas

+ Loading Dock Access & Safety Barriers – Critical for safe loading and unloading of recyclable materials.

Best Practice: Regularly inspect and maintain

all access systems to ensure continued compliance and worker safety.

Crossover bridges and stair platforms allow safe passage over pipelines, conveyors, and high-traffic areas, reducing trip hazards and ensuring uninterrupted workflow.

Protect Workers & Equipment with Safety Barriers

Safety barriers are an essential investment in waste and recycling facility safety. From pedestrian walkways to machine guarding and vehicle impact protection, Safetylyne provides tailored barrier solutions designed to keep your facility safe and compliant.

+ Custom-designed pedestrian barriers, guardrails, and traffic bollards

+ Loading dock edge protection and elevated walkway barriers

+ Machine safety guardrails for conveyors, balers, and processing equipment

Best Practice: Install guardrails and fixed safety barriers around shredders, balers, and sorting conveyors to prevent accidents.

Enhancing Educational Engagement Through Safe Observation

Safetylyne's access solutions extend beyond operational efficiency and safety; they also facilitate educational initiatives. For instance, the inclusion of a gantry or viewing platform in a recycling facility allows school groups and visitors to safely observe the recycling process firsthand. These platforms are designed to provide a secure vantage point, enabling educational tours that promote community awareness and understanding of recycling practices.

Safe Work Practices for Hazardous Waste Handling

In waste management facility maintenance, handling hazardous materials presents unique height safety challenges. Workers need secure, controlled access to prevent exposure, ensure safe movement, and enable rapid emergency response. Properly designed access systems help mitigate risks, improve operational efficiency, and maintain compliance with safety regulations.

Key access solutions include:

Handling hazardous waste (chemical, medical, or electronic) requires additional access considerations, including:

+ Enclosed walkways to limit exposure to airborne particles

+ Non-slip surfaces and spill-resistant flooring to prevent chemical hazards

+ Specialised access platforms for handling large storage containers and incineration units

+

Fall protection systems for high-risk areas

Emergency Access & Evacuation Routes

Hazardous waste facilities must be designed with unobstructed emergency access to allow quick response in case of spills, fires, or containment failures. Essential safety measures include:

+ Clearly marked escape routes with dedicated, obstruction-free pathways

+ Fire-resistant stairs and walkways to ensure safe emergency evacuation from elevated structures

+ Secure access to fire suppression systems and emergency equipment to support fast, effective response

By integrating purpose-built access systems, facility managers can ensure safe handling, compliance with height safety standards, and improved emergency readiness in hazardous waste environments.

GOT A QUESTION ABOUT ACCESS SOLUTIONS?

For top-quality, custom-engineered access solutions for your facility, contact Safetylyne today. Our experts are ready to provide comprehensive safety audits, recommendations, and installations to ensure the highest level of safety and efficiency for your operations.

TALK TO HEIGHT SAFETY EXPERTS ABOUT YOUR PROJECT TODAY: